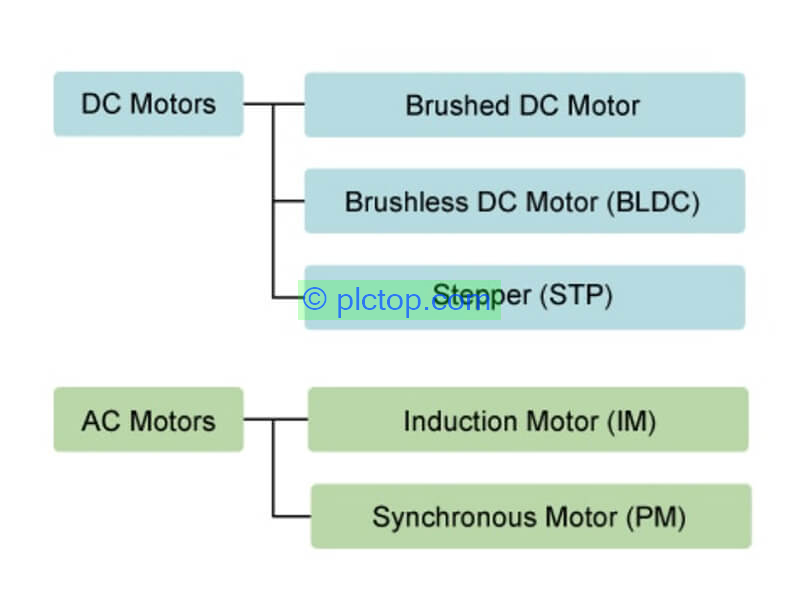

1. What is an electric motor? Classification of electric motors

Currently, many types of engines are commonly used by people. Among them are motors capable of converting electrical energy into mechanical energy. Among these, brushless motor (abbreviated as BLDC) has high working efficiency and excellent controllability, so it is widely used in many fields.

BLDC motors have the biggest advantage of saving electricity compared to other types of electric motors. Therefore, now there are many places to sell brushless motors for customers to choose freely.

The motors are different, depending on the type of power (AC or DC motor) and the method of generating the rotations. Brushed DC motor is a type of motor with simple design and easy control, so it is widely used to perform opening and closing of the disc tray.

In automobiles, brushless dc motors are commonly used for the retraction, expansion and positioning of electrically operated side windows. A typical stepper motor will be pulse driven and it will rotate through a specific angle (step) with each pulse. Since its rotation is precisely controlled by the number of pulses it receives, these motors are widely used to perform position correction.

With a synchronous motor, the rotation is in sync with the frequency of the current it supplies. These motors are commonly used to drive rotating trays in microwave ovens.

Gears with a reduction function in the motor unit can be used to help achieve the proper rotational speed through which the food can be heated. The same is true for an induction motor, its rotational speed will vary with frequency, but the motion is asynchronous.

2. What is a brushless electric motor?

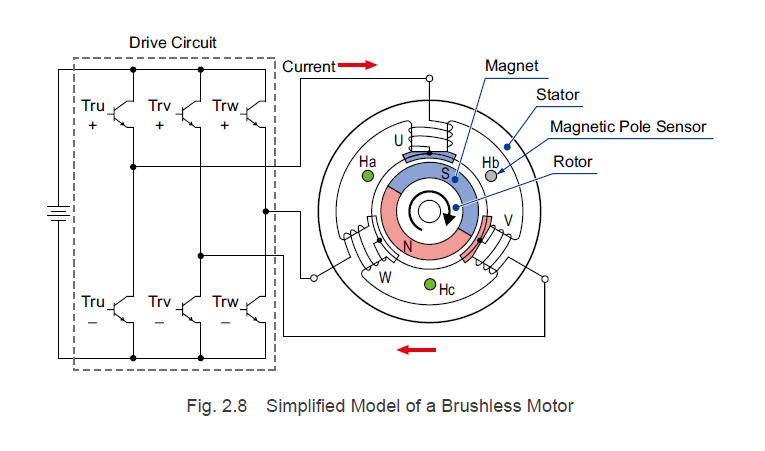

A brushless motor (BLDC) is an electric motor that relies on a permanent magnetic field and a sensor to determine its position, completely without using brushes (brushes) to help eliminate friction. From there, it helps to reduce the noise for the engine to operate smoothly, and at the same time save electricity.

Similar to common synchronous motors, the windings of the BLDC are also placed at an angle of 120 degrees from each other in the space of the stator. The magnets are also firmly attached to the rotor body, capable of exciting the motor.

In particular, the operation of the mini brushless motor requires a rotor position sensor to help the motor operate better.

3. Brushless motor construction

Brushless motor consists of the following parts:

- Stator: Usually consists of iron cores (electrical engineering steel sheets are insulated together) and windings. The winding of a brushless motor is also different from that of a conventional 3-phase AC motor.

- Rotor: Basically, this part is similar to other permanent magnet motors.

- Hall sensor: Due to the characteristic of the BLDC motor’s anti-electromotive force, it has a trapezoidal shape, so its normal control configuration also requires a sensor to determine the position of the rotor magnetic field in relation to the winding phases. stator. To do that, people often use Hall effect sensors, which can be called Hall sensors for short.

4. Working principle of brushless motor

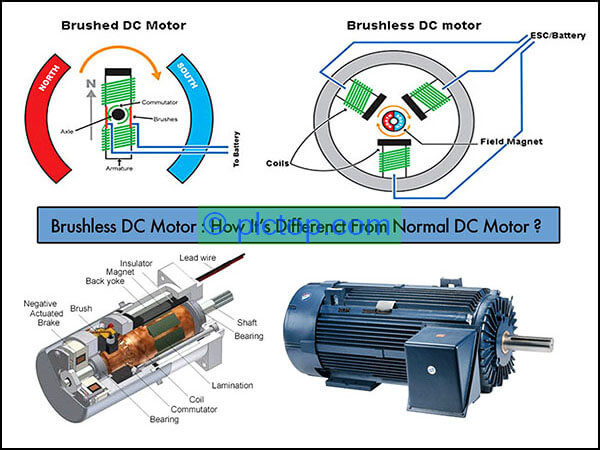

As the name implies, brushless DC motors are characterized by the use of no brushes. With brush motors, the brush will pass current through the commutator to flow into the windings on the rotor.

Brushless motors do not transmit current to the rotor windings because the windings are not on the rotor at all. Instead, the main rotor is a permanent magnet, it has coils that do not rotate but are fixed in place above the stator. Since these coils do not move, neither a brush nor a commutator is needed.

In a brushless motor, the permanent magnet is rotated by changing the direction of the magnetic field generated by the coils arranged stationary around it. To control that rotation, you need to adjust the magnitude of the combined direction of the current flowing into these windings.

5. Brushless motor advantages

- A big advantage of these motors is efficiency, as they can be driven continuously while at maximum rotational force (also known as torque). In contrast, brush motors will achieve maximum torque only at certain points within the rotation. This is also the reason why even a mini brushless motor can provide significant power.

- The second great advantage of brushless motors is the ability to control their operation well. The BLDC motor is controllable, using a feedback mechanism to accurately distribute the torque and rotational speed desired by the user. The precise control also reduces energy consumption and generates less heat, if it is a battery powered motor it also helps to prolong the life and durability of the battery.

- The BLDC motor is also considered a motor with high durability and low electrical noise because it has no brushes. With a brush motor, the brush and commutator will be worn out due to constant, frequent motion contact and also generate sparks and heat at the point of contact.

- In particular, electrical noise is considered to be the result of strong sparks that will frequently appear in the areas where the brush passes through the openings inside the commutator. This also explains why BLDC motors are generally considered to be more suitable for applications where electrical noise is to be avoided.

6. Application of brushless motor

Brushless motors have long been used in the construction of washing machines, air conditioners, and other household electronics. And recently, this motor has also appeared in fans, because of their high efficiency, which has significantly reduced the amount of power consumed for the fan.

BLDC is also being used to operate the vacuum cleaner. In some cases, a change in their control program setting will result in a major breakthrough in rotational speed. This is an example of the first-order controllability of these motors.

Brushless motors are also being used to spin hard drives. Because of their durability, the drive will last longer for a long time. At the same time, the energy efficiency of the engine also contributes to reducing energy consumption.

The BLDC engine is also ideal for drone applications. Their precise position control makes them particularly suitable for multi-cruise drones, which are controlled by precisely controlling the position and rotational speed of each propeller.