Loadcell is an important measuring device that helps electronic scales operate stably and accurately. So what is a load cell? Structure, principle and how to test loadcell? Refer to the following article for more useful information.

What is Loadcell ?

What is a loadcell sensor? Loadcell also known as load cell, this device is used to convert torque or weight force into an electrical signal.

Loadcell sensors are often applied in electronic scales such as: bench scales, industrial electronic scales, hanging scales, technical scales, conveyor scales…

Working principle of Loadcell

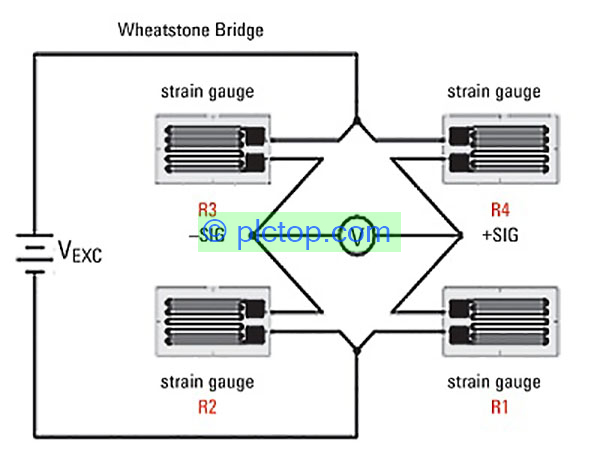

Loadcell works on the principle of “Wheatstone”

When there is a force acting on the loadcell, the loadcell body will be stretched or compressed. Since then, the length of metal strain gauges glued on the loadcell body changes, causing the value of the resistors to change accordingly. The output voltage continues to change, this data will be converted into digital form by the amplifier of the electronic scale.

Specifications of Loadcell

+ Accuracy: Shows the percentage accuracy of the measurement. Accuracy will depend on non-linearity, delay and repeatability.

+ Rated capacity: the maximum weight value that the load cell can measure.

+ Temperature Compensation Range: Amount of heat to which the Loadcell output is compensated

+ Degree of Protection: Rated according to the IP scale, the IP index represents the degree of protection against ingress of water and dust.

+ Voltage: the loadcell’s operating voltage value (5 to 15 V).

+ Latency: A delay that occurs when displaying results leads to errors in the results.

+ Input impedance: Determined through S- and S+ when the loadcell is not connected to the system or in idle mode.

+ Insulation resistance: Insulation value of the Loadcell metal shell and current connection equipment.

+ Mechanical failure: the value of the load at which the load cell can break, fail or deform.

+ Output value: The measured result, usually in mV.

+ Output Impedance: Same as input impedance but measured via Ex+ and EX-, in unconnected loadcell condition or in idle mode.

+ Safe Overload: The capacity the Loadcell can exceed.

+ Temperature Impact Factor: Measured under load mode, this is the change in the capacity of the Loadcell under the change of temperature.

+ Temperature impact factor at zero point: same as temperature impact factor but measured at no-load.

Common types of Loadcells

+ In-Line Load Cell: is the most common type of load cell. Commonly used for both tension and compression load measurement applications. Load Cell In-line sensors provide high accuracy, rigidity and durability with minimal installation clearance required.

+ Column Load Cell: is a type of sensor designed with a vertical cylindrical shape. This design is commonly used in high-volume compression applications such as clamping force testing of CNC machines. Force cell models with this design typically provide robust capacities from 2,000 to 30,000lbs .

+Load Button: are force sensors with a flat surface, the design of the middle part is slightly raised like a push button, this is also where the pressure is applied. The highlight of this type of design is that they do not fight too much area, although small but have good durability. This type is commonly used to measure the loading force of rolling components.

+ S-Beam Load Cell: is a force sensor with a unique design, sometimes also called Z-Beam or S-Tye, you can see the design is quite similar to the letter S or Z. This compact meter is well suited for in-line control feedback and dynamic condenser control, cable tension measurement, in addition it can also be used as a non-contact flow sensor for flow measurement. amount of fluorine with high accuracy.

+ Thru-Hole Load Cell: also known as a washer with a hole in the middle, a common through-hole sensor with a smooth (non-threaded) inner part is used to measure the compression force of the passing rod. its center, usually used to measure the force of the bolt.

+ Pancake Load Cells: has a hole in the middle, a threaded hole, often used to measure load forces in tension or compression. Typically used in applications where high durability, long life or high capacity in-line measurements are required for tank weighing systems. Threaded design for good deflection resistance.

+ Rod-End Load Cell: single male and female threaded connection design suitable for applications where the green sensor needs to be adjusted to any fixture.

+ Single Point Load Cell: side mounted force sensor with single point design specially made for OEM applications requiring high accuracy or high volume production. Can be used flexibly in tension and compression applications.

Thanks for Views 😀