ModBUS communication protocol with the advantages of high integration and scalability, stable transmission speed and very long transmission distance (about 1200 meters on average). It is because of these advantages that modbus communication today is being widely developed to replace traditional forms such as analog (4-20mA, 0-10V,…) or digital.

Especially the ability to integrate with the internet environment of modbus tcp/ip protocol. With just an internet connection, we can observe everything in the factory from temperature sensor pt100, liquid level sensor, pressure sensor,…. as well as control the operation of these devices.

And of course, everything works, as long as these devices support the modbus protocol.

What is Modbus Communication?

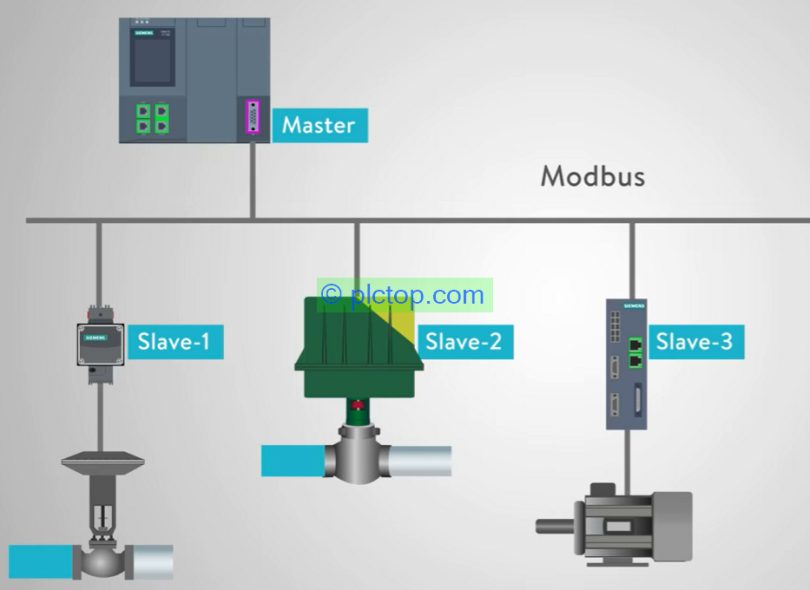

To put it simply, modbus is a type of data transfer protocol used to communicate between devices. Modbus will include 1 device as master and 1 device as slave. In which, the master has only 1, and the slave can be up to 252 devices in series. Slaves can be devices used in the factory such as temperature sensors, pressure sensors, water level sensors, etc. When the Master needs information about the slaves, it will send a signal to the slaves. . The slave will then send a packet to reply to the master.

Modbus it is like the old 4-20mA or 0-10V analog signal. If before, 0-10V signal is often used and taught a lot. Then the 4-20mA signal gradually replaces the 0-10V signal type. And now, modbus is gradually replacing the standard 4-20mA to become the most popular form of communication.

Development History?

Modbus is a communication standard introduced in 1979 by the Modicon Company. At this time, the modbus standard was created with the purpose of being used with the company’s PLC.

And now, the Modicon company is owned by Schneider Electric.

The development and updating of modbus protocols are managed by the Modbus Organization.

The Modbus Organization is an association of users and equipment vendors that use the Modbus standard.

Why was Modbus born?

As we all know, each manufacturer will have their own proprietary and different communication protocols and programming languages. This will be a difficulty if a 3rd party wants to read and communicate data to its device. And certainly the manufacturers they don’t want that either.

Therefore, the ModBUS communication standard was born. With the advantage of being an open protocol, it only provides a common platform, all parameters are published. And then, firms will directly participate in editing and programming at their discretion on the Modbus platform.

A simple example that you can imagine is Google’s Android operating system. In android, google they will only provide 1 main platform, and phone manufacturers like Samsung, Oppo, Xiaomi, … will directly edit android to their liking.

This is extremely important because it will help devices between brands work perfectly and stably with each other.

And more is the ability to integrate many types of devices in the same application.

Advantages of modbus communication:

- Supported by many manufacturers, software vendors and groups of programmers co-developed.

- The ability to integrate devices of many manufacturers in the same specific application.

- Fast communication time, long communication distance (average 1200 meters).

- Ability to integrate via webserver, internet.

- Scalability to multiple devices.

- High economic efficiency, can connect several hundred devices with only 2 wires.

Modbus communication types for industrial use:

Modbus communication includes 3 types of modbus: Modbus rtu, modbus tcp/ip and modbus ascii. Of which the most used are modbus rtu and modbus tcp/ip.

With the Modbus RTU type, people will use the RS232 or RS485 serial port to connect. As for the TCP/IP modbus, the communication port is the RJ-45 port, which is a normal internet cable port.

Here we will go into understanding each of the following modbus types:

Modbus RTU

Modbus RTU protocol is an open protocol, using RS-232 or RS485 physical communication port for data transmission. Its operating model is Master-Slave.

This is a widely used protocol in many fields of automation, industry, etc. because of the advantages of stability, simplicity, ease of use.

Modbus TCP

This is a kind of modbus that uses RJ45 communication port, ie normal internet port. The data communication will be done through the web server.

These web servers will display technical specifications as well as be able to control devices in the factory remotely. Details about this protocol, we will learn in another specific article.

Modbus ASCII

Another type of modbus that you may not see in the factory is the ASCII modbus. This is a type of modbus in which users can read packets directly without going through master devices.

Therefore, modbus ascii cannot communicate with modbus rtu and vice versa.

Modbus Plus

This is a Schneider Electric exclusive modbus and unlike other variants. It supports peer-to-peer communication between multiple masters.